- +91-9811502692

- +91-99220 07505

- krishan@cuttech.in

- rohit@cuttech.in

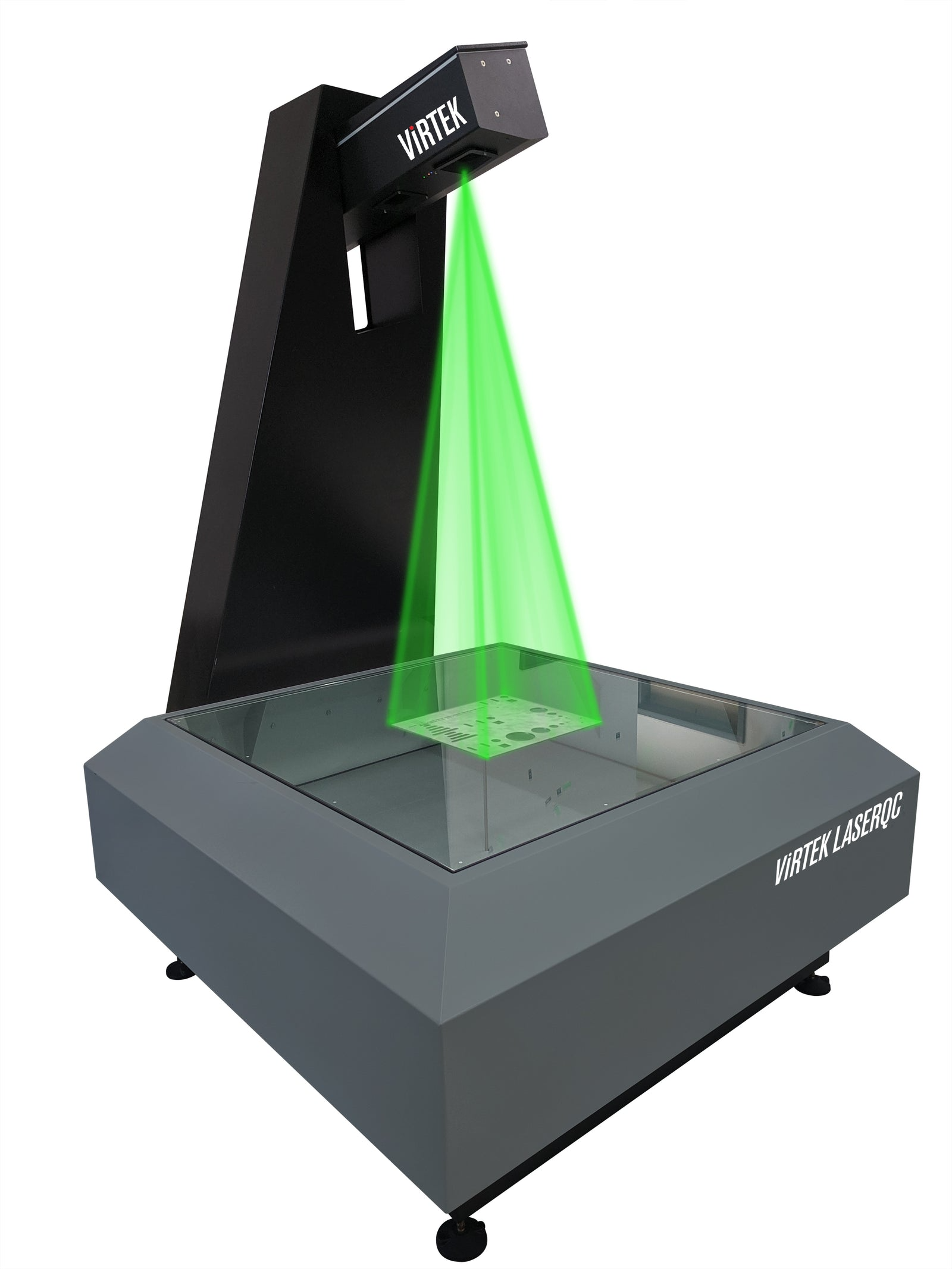

Virtek Laser QC

LaserQC@ delivers bottom-line results

Laser Fast (and Easy)

LaserQC@ captures over 500 data points per second to make part inspections laser-fast, right on the shop floor

Designed to set up easily so your system is up and running in less than a day. The intuitive user interface allows new operators to become fully proficient within just a few hours.

Laser Accurate

The system quickly performs 100% inspections accurate to ± 0.002″ (0.05mm) for 2D measurements and ± 0.010″ (0.25mm) for formed measurements.

Shop Floor Friendly

LaserQC@ offers a reliable, low-maintenance solution that operates along side your facilities CNC equipment.

The system self-calibrates and adjusts system settings to accommodate for environmental changes common to the shop floor.

Additionally, Virtek offers a Part Stabilizer add-on, created specifically for use in the gasket and seal industries.

Get the Edge in 2D and Formed Part Inspection

First Article Inspection

Integrating laser inspection on your shop floor translates into more ‘green-light’ time for your production equipment.

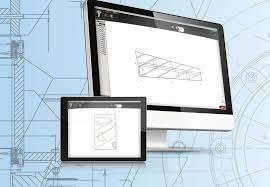

Accuracy Dashboard

LaserQC@ makes first part inspection fast and easy with no special training required. Color codes indicate any part deviations.

2D Reverse Engineering

The scanning process captures the complete profile of existing parts or templates at laser speed.

SPC & Quality Reporting

Inspection data from the LaserQC@ is saved as CAD files, from which can generate color inspection reports to your specifications.

Applications

ViRTEK IRIS 3D

Laser templating and positioning systems accurately project a virtual laser template onto molds and parts to guide operators through part fabrication whether it be ply layup, paint masking, assembly, or part placement. Virtek Iris™ significantly advances laser-guided assembly with new integrated vision technology, innovative “FlashAlign” functionality, superior high visibility laser- -line, and new multi-tasking capabilities. The thin-client experience boasts a unique offering. Initial alignment is 20X faster and re-alignments are reduced from minutes to seconds – saving time, and increasing workflow productivity, all while retaining quality and accuracy.

Applications

Features

FlashAlign™

Multi-Tasking

Production Reporting Database

Auto Focus & High Visibility

Simplified Software Interface

Projected Cross Hair

Field Replaceable Components

Projected Menus

Focus of Attention

Multi-Tasking

Production Reporting Database

Auto Focus & High Visibility

Simplified Software Interface

Projected Cross Hair

Field Replaceable Components

Projected Menus

Focus of Attention

Benefits

Instant alignment of the part or tool virtually eliminating set up time.

Multi-Tasking enables one projector to serve multiple workstations so ply layup on multiple parts can occur in parallel. The new thin client experience allows you to use one Iris 3D license to connect several PCs or tablets to serve as clients.

Easily access any Iris 3D system to retrieve instantaneous feedback on production status or retrieve historical data detailing the completion of each step in any production work-flow executed in the past.

Auto-Focus fiber connected laser source with optional long range optics. Provides operators with a brighter, safe laser delivering superior visibility even in the brightest work environments.

Reduced training & fewer operator errors, simplified operation and administration.

Automatically project crosshairs to indicate drill locations, punch locations, assembly positions. Crosshairs work on both flat and curved surfaces.

Flexibility of onsite repair of multiple components within the system such as laser, and cooling fan helping to reduce cost of ownership.

Work seamlessly from anywhere with remote capabilities, using the projected menus on the tool or part, or using the wireless remote controller at a 45m range.

Reduces projection flicker on-demand by limiting the projection to just the area of interest for increased visibility.

Cuttech ViRTEK IRIS TRUSS for Steel

NEW HIGH VISIBILITY LASER PROJECTOR LPS-10.

Operators will reap the benefits from a brighter, safe laser, that delivers increased visibility even in the brightest work environments.

Laser Templating solutions for roof truss, plus wall panel assembly.

The Virtek® Iris™ Truss system projects a laser template of the truss onto any work surface, highlighting the position and shape of all truss joints position of chords, webs, tags, plates, and much more. This eliminates the need for measuring, squaring and stringing. Even the most complex trusses are assembled in minutes. It makes manufacturing so easy that even less experienced workers are instantly productive.

Did you know? You can use lasers for floor and roof truss assembly and production.

- Support for 64-bit systems

- Reduce production time by up to 30%

- Enhanced and faster communication and automatic calibration

- Virtually eliminate operator errors that result in costly rework

- Real-time production monitoring

Benefits of Iris™ Truss

- Reduce jigging time by up to 70%, compared to manual measurement.

- Laser-guided assembly eliminates the need for comprehensive training, New employees are instantly productive during the build process.

- 100% validation, to ensure as designed is as built.

- Virtek has over 15,000 projectors in use today in over 600 manufacturing facilities.

- Laser Projected Menus allow for greater build efficiencies as the software can be controlled by the builder at the table.100% heads down production!

- Ensure accuracy and quality with guided placement of chords and plates.

- Seamless integration with automated jigging systems.

- Recall previous designs to rebuild damaged trusses.

- Creates efficiencies by controlling the truss view and the selection of trusses right from the work surface with projected icons for each jig station,

- Connect projectors together to cover virtually any length of table.

- Setup multiple jig stations to work on several trusses with independent work flows at one time.

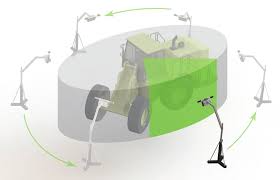

Cuttech ViRTEK IRIS Active Track

NEW REAL-TIME TRACKING SOFTWARE WITH VISION SYSTEM!

Virtek’s newest software, Iris™ Active Track helps manufacturers complete inspection and assembly tasks effortlessly on moving parts. Iris™ Active Track is able to project a stable, accurate laser line directly onto a moving surface, in 3D, to provide operators with the information needed to get the job done more efficiently.

Active Track

Benefits of Active Track

- Complete inspection and assembly tasks effortlessly on moving tools

- Inspect Automated Fiber Placement (AFP) ply boundary while a tool, such as a mandrel, is in motion

- Gain more productive time during inspection, component assembly, or manual layup processes

- Displaces manual measurements and marking

- Great for assembly procedures without the need for fixturing

- Maintain the quality of end product

- Eliminates templating process steps and template costs

- Eliminates costly human errors

- De-skill complex tasks

- Simple, easy to learn, and low maintenance

Cuttech Virtek Iris™ SPS

ABOUT IRIS™ SPS

The Iris Spatial Positioning System combines the laser projection technology with 3D vision technology to locate a part in 3D space then quickly locks onto its CAD-specified assembly position. Iris SPS helps accelerate the assembly process by eliminating manual measuring, marking, templating, and fitting.

High Visibility Laser Provides operators with a brighter, safer laser delivering superior visibility even in the brightest work environments

Iris SPS Functionality Offers Advanced Features

CAPABILITIES TO DELIVER OPERATOR GUIDED ASSEMBLY USING LASERS. A SIMPLE, INTUITIVE LASER PROJECTION PACKAGE ANYONE ON THE SHOP FLOOR CAN USE. IRIS SPS IS STANDARD FUNCTIONALITY THAT ALLOWS EVEN THE MOST COMPLEX ASSEMBLIES TO BE MASTERED.

Panoramic Projection – Move the part or the system and instantly project from another viewpoint.

Core provides assembly power without complication

• Build complex parts as easily as simple parts

• Scalable projection platform to adjust to project size

• Use it to aid traditional processes, or manufacture in ways you never could

• Flexible; MOVE IT AND IMMEDIATELY USE IT!

• Clean interface guides users to best choices

Iris SPS is certified for use with Virtek’s Locator, and LPS-7 configuration or with the new VPS system applications.

Benefits of Virtek Iris™ SPS

- Instantly adjusts projection if the part is moved while maintaining accuracy.

- Multiple measurements are captured to optimize accuracy to counter the effects of lighting changes such as welding flashes.

- Ability to use two spatial locators and laser projectors to cover large parts easily.

- Ability to project from any point of view, on to any surface 360 degrees around the part. Simply point and project instantly, projections are bound together into a single coordinate system.

- Improve alignment by measuring datums as they are assembled. Speed up alignment by measuring only actively required datums.

- Flexibility of onsite repair of multiple components within the systemComponents such as laser, galvos, and fan helping to reduce cost of ownership.

- Projected menus are intuitive visual aids that assist the operator through the workflow by displaying text and icons directly on the work surface such as the next part number in the process. Work seamlessly from anywhere with remote capabilities, using the projected menus on the tool or part.

- Reduces projection flicker on-demand by limiting the projection area for increased visibility.

Cuttech Virtek Iris Truss

NEW HIGH VISIBILITY LASER PROJECTOR LPS-10.

Provides operators with a brighter, safe laser delivering 30% more visibility, even in the brightest work environments.

Laser Templating solutions for roof & floor truss, plus wall panel assembly. The Virtek® IrisTM Truss system projects a laser template of the truss onto any work surface, highlighting the position and shape of all truss joints position of chords, webs, tags, strong-backs, plates, posi-struts and much more. This eliminates the need for measuring, squaring and stringing. Even the most complex trusses are assembled in minutes. It makes manufacturing so easy that even less experienced workers are instantly productive.

Did you know? You can use lasers for floor truss, floor cassettes and wall panel production.

- Designed a new software package just for floor truss production

- Support for 64-bit systems

- Reduce production time by up to 30%

- Virtually eliminate operation errors that result in costly rework

- Real-time production monitoring

Benefits of Virtek Iris™ SPS

- Reduce jigging time by up to 70%, compared to manual measurement.

- Laser-guided assembly eliminates the need for comprehensive training. New employees are instantly productive during the build process.

- 100% validation, to ensure as designed is as built

- Virtek has over 15,000 projectors in use today in over 600 manufacturing facilities.

- Laser Projected Menus allow for greater build efficiencies as the software can be controlled by the builder at the table.100% heads down production!

- Ensure accuracy and quality with guided placement of chords and plates.

- Seamless integration with automated jigging systems.

- Recall previous designs to rebuild damaged trusses.

- Creates efficiencies by controlling the truss view and the selection of trusses right from the work surface with projected icons for each jig station.