- +91-9811502692

- +91-99220 07505

- krishan@cuttech.in

- rohit@cuttech.in

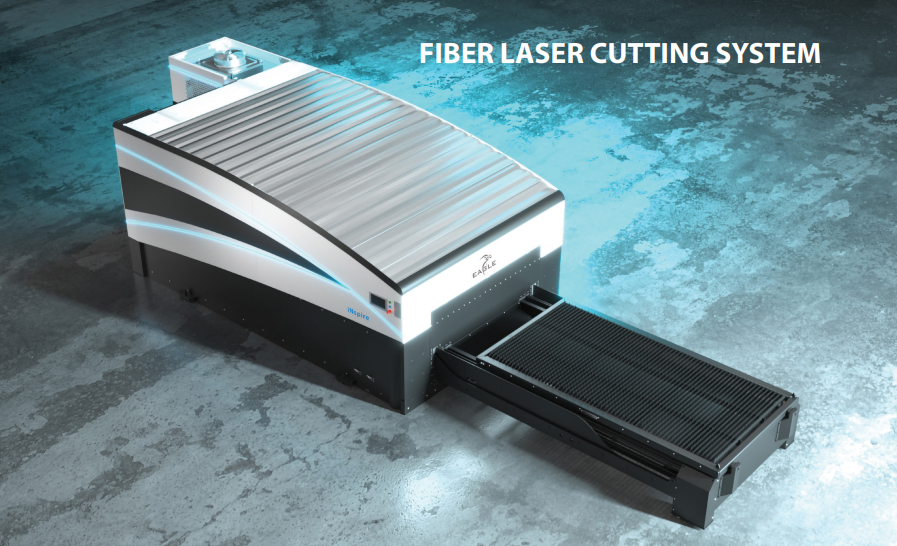

Eagle iNspire Cutting Machine Specifications

iNspire

The iNspire series presents state-of-the-art machines with extremely precise, and exceptionally fast solutions for the most demanding mass production applications where speed, power, and reliability are a must.

With cutting speeds up to 150m/min, top positioning speed of 340m/min, dynamic acceleration up to up to 6G, and fiber laser

powers from 1 to 40kW, they are the fastest and most efficient laser machines in the world.

STANDARD EQUIPMENT

Benefits of iNspire

- Made for 24/7 automation

- Wider range of material thicknesses

- Highest efficiency and precision

- Unmatched dynamic acceleration and fast pallet changer

- Lowest maintenance on the market

- Reduced energy consumption

- Intelligent construction and design

- Lowest cost per part

- Highest throughput quality and burr-free

- Best performances and reliability on the market

Eagle FlowIN Cutting Machine Specifications

FlowIN

FlowIN is an integrated system designed for continuous material flow, simultaneous cutting, and sorting. It ensures that every

part, regardless of shape or thickness, can be sorted, just as efficiently as the machine cuts. You just feed material to the machine

and receive ready cut, free and sorted parts out the other end.

FlowIN is built for metal sheets and FlowINCo is the coil-cutting version featuring the same machine parameters.

STANDARD EQUIPMENT

Benefits of FlowIN

- No more skeleton

- No more combs

- No more comb cleaning

- No more comb cutting

- No more pallet changer

- No more welded parts

- No more slugs

- No more shape restrictions

- No more thickness limitations

- No more inefficient nesting

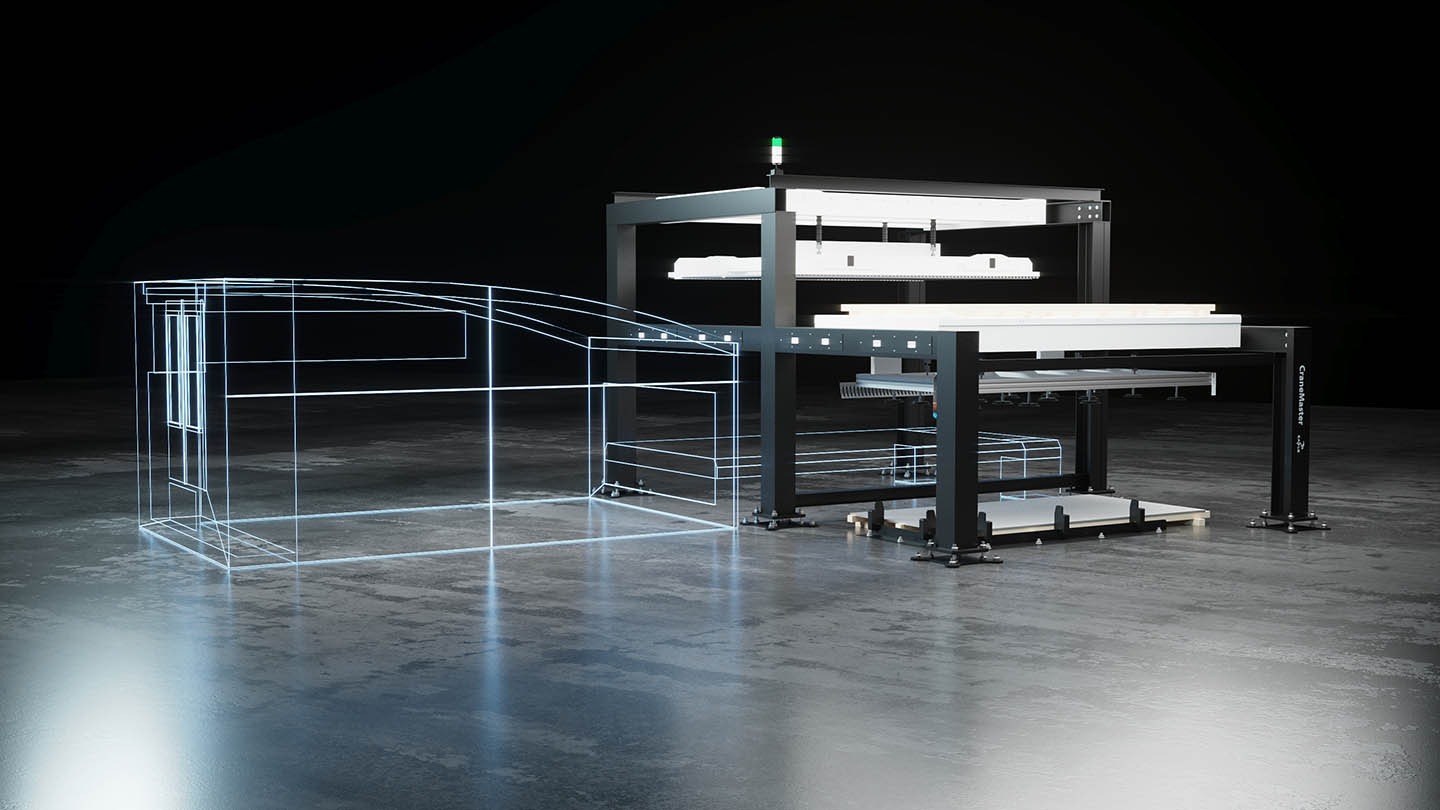

Eagle Automation Specifications

CraneMaster

The CraneMaster is a loading/unloading system designed to simultaneously load new material and unload cut parts for smooth production and enhanced efficiency. There are two available versions with air suction cups at either the top or bottom of the system. Thanks to its highly efficient cycle time, the CraneMaster contributes to the overall costeffectiveness of the manufacturing process and is recommended for companies with medium to high volume production.

Automation Specifications

eTower1

The eTower1 Is a single tower storage system equipped with a loading/unloading station and universal shelves that can be used for raw material as well as for cut parts and remnants. It consists of a transport column equipped with a moving lift that transports the palettes between the storage shelves and the loading/unloading station. The automated lift picks up a pallet containing raw metal sheets and takes them to the CraneMasterStore. The CraneMaster then places them onto the machine’s pallet changer and simultaneously removes the cut parts to be stored. The standard eTower1 system comes with 10, 15, or 20 shelves but can be customized according to your needs. In addition, it features a control panel that allows you to manage material storage and retrieval throughout your facility. The CraneMaster and eTower1 work seamlessly to optimize process logistics and material preparation and guarantee high storage density. Together, these automated systems make 24/7 unsupervised production possible helping you achieve the highest productivity