- +91-9811502692

- +91-99220 07505

- krishan@cuttech.in

- rohit@cuttech.in

CSM CNC Tube Bending Machines Product

CNC Tube Bending Machines Machine Product

CSM’s CNC tube bending machines, available through CutTech, set the global standard in tube bending technology. With over 24 international design patents, these machines offer exceptional performance and flexibility for processing metal tubes.

Key Features:

- Planetary Gear Transmission System: Ensures smooth, high-precision bending with consistent results across all tube diameters.

- Range of Capability: Can bend various diameters of tubes ranging from 6 mm up to 254 mm, thus it is well suited for the varied size tubes that exist in most industries.

- Advanced Control System: With great ease through user friendly CNC control, the complex bending pattern is achievable, and time cycles are reduced.

- Durability & Reliability: Durable parts are used to ensure long-lasting performance even at demand-high usage times.

- CSM’s CNC Tube Bending Machines: The PRECISION and EFFICIENCY That Industries Like Automotive, Aerospace, Construction, and Manufacturing Require for Small- and Large-Scale Production.

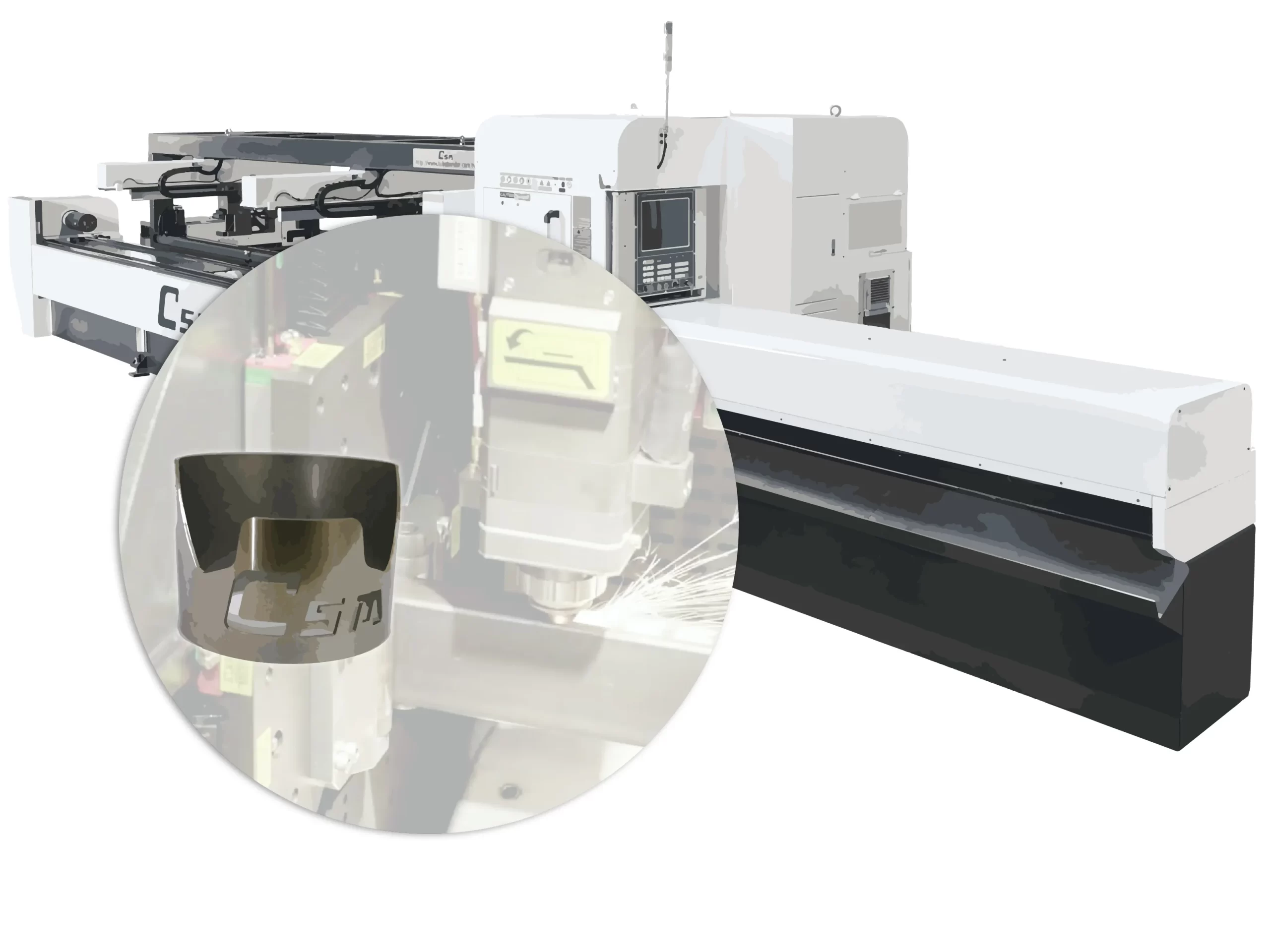

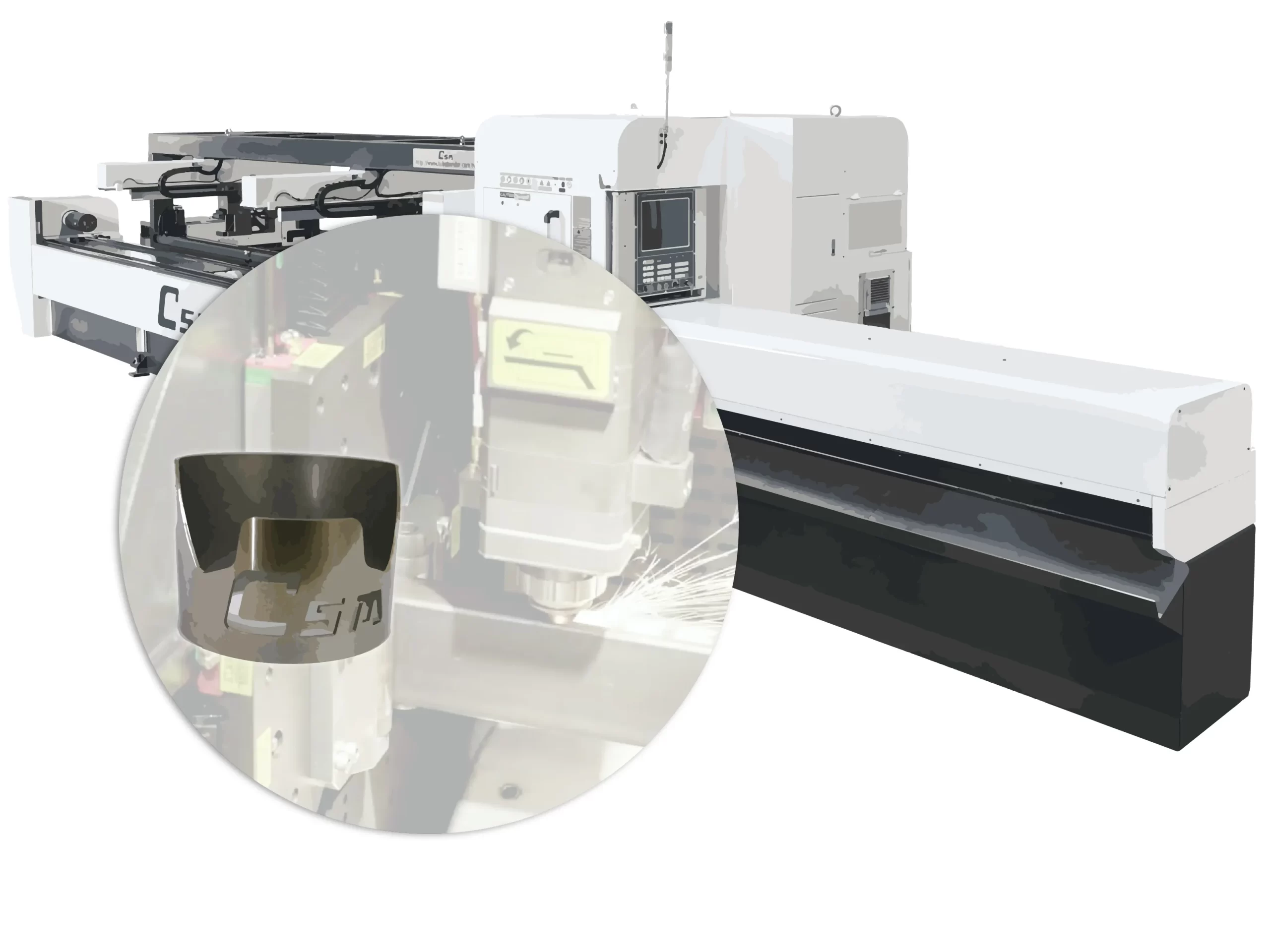

CSM Laser Cutting Product

Laser Cutting Product

CutTech Company is pleased to introduce CSM’s newest tube laser cutting technology, specifically designed and engineered for precision and versatility. Tube laser cutting machines from our brand are equipped with international design patents and 5-axis simultaneous movement technology that ensures leading-edge performance in cutting for the most complex geometries of tubes.

Main Features:

- High Precision: Position accuracy up to ±0.03 mm, with the highest possible detail and precision.

- High Speed Motion System: 5-axis simultaneous movements allow for complex and precise cuts at a variety of angles and orientations.

- Energy Saving: Designed using energy saving technology to reduce the cost of running.

- Versatility: Cuts tubes in different materials and thicknesses, providing flexibility for unmatched applications.

Laser cutting by CutTech and CSM is suitable for industries that require high-speed and high-precision cutting of tubes without having wastage of material.

CSM End Forming Product

End Forming Product

CutTech’s end forming machines by CSM help in making the best quality of end-formed tubes with minimum accuracy and speed. These are inevitable pieces of tube fabrication, where it provides versatility along with reliability for creating different tube end shapes for numerous applications.

Key Features:

Precision End Forming: It is capable of performing operations involving flaring, swaging, reducing, and beading, with a pretty high degree of precision.

Multiple Industries: Being widely applicable in various industries, such as automotive, HVAC, plumbing, and manufacturing, where specific shapes are necessary in the assembly or connection of tube ends.

Customized: The end forming process can be designed for varying sizes of tubes and processes, allowing for flexibility in design and production.

High Throughput and Excellent Quality: The machines are engineered for high throughput, thus reducing cycle time, but without compromising accuracy and quality in end forming.

With CSM’s advanced end forming machines, your tube parts are guaranteed to meet extremely stringent specifications for functionality and durability.