- +91-9811502692

- +91-99220 07505

- krishan@cuttech.in

- rohit@cuttech.in

Slide

Apparel Services Provide By Cuttech

Slide

Apparel Services Provide By Cuttech

Slide

Apparel Services Provide By Cuttech

AUDACES 360

Audaces360 is a comprehensive solution that promises to revolutionize the way you approach textile and fashion design. Our innovative platform seamlessly integrates the creative and productive phases, empowering you to unleash your imagination and achieve higher levels of productivity. With Audaces360, you will have everything you need to optimize your design process and reduce raw material costs, without compromising on quality.

Our features include:

ISA

Plan and manage your collection in real time with our Fashion Product Lifecycle Management (PLM) software

IDEA

Create precise vector drawings,

tech packs, and automated pre-cost

estimates for your designs

FASHION STUDIO

Design your garments directly in a three-dimensional environment, with complete creative control

DIGI FLASH

Digitize your paper patterns quickly

and easily, capturing all the details with

a simple photo

PATTERN

Create accurate patterns and

grade sizes with ease directly on

your computer

MARKER

Increase efficiency by automatically creating fabric markers

SUPERA

Optimize your fabric usage and

save time by managing your

marking queues

3 D

Sew your patterns and preview

the fitting with stunning realism

using 3D avatars

SHAPE-U

Boost your e-commerce success with our software which combines intelligent size recommendation tools, measurement charts and data insights

AUDACES LINEA

Accelerate your production and marketing efforts with the Audaces Linea spreader. With just a few clicks on the

machine’s touch screen, you can program multiple spreadings in a single day, giving your company autonomy and dynamism, in addition to improved product quality

- Technical features:

- Optional accessories:

- Standard accessories:

x Maximum speed: 100 m / min

x Useful spreading width: 180, 220 and 240 cm

x Roll weight capacity: 50 kg and 100 kg

x Roll diameter: 60 and 80 cm

x Maximum spreading height 22 cm

x Cradle with belts and automatic lift

x Color touch screen with self-diagnosis system

x Fixed catcher

x Movable catcher

x Folding unit (zig-zag)

x Kit for inverting rolled fabrics for spreading

x Table for spreading of relaxed fabrics

x Accessory for elastic fabrics

x Kit for spreading bulky rolls outside the cradle

x Accessory for tubular fabric

x Multi-cut spreading software with variable colors

x Network connectivity

x Roll loading systems

x Electronic fabric tension control system

x Selvedge alignment by photocells installed on a mobile base

x Memorization of different spreading programs

x Cutter with variable speed and automatic lif

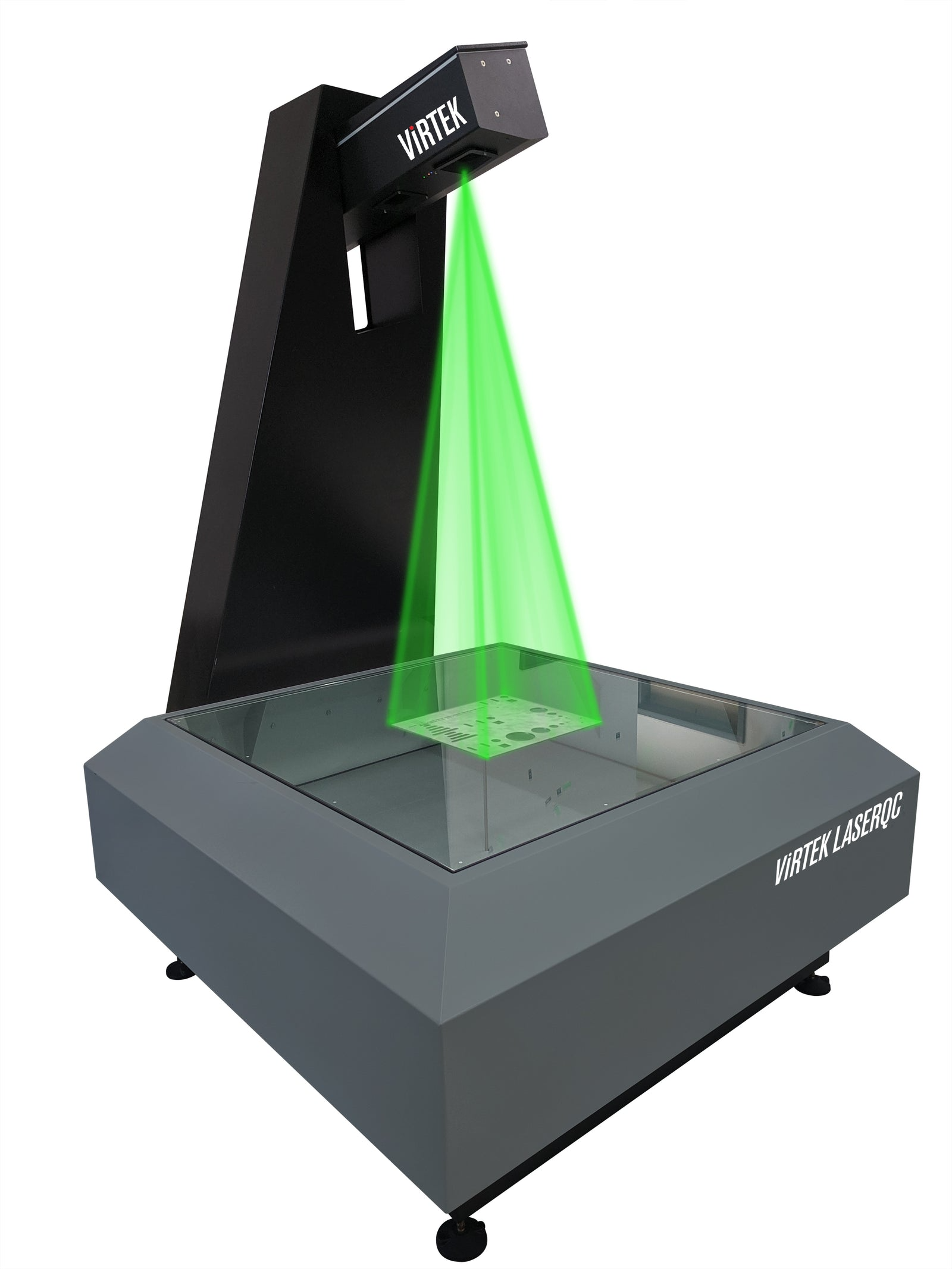

Virtek Laser QC

LaserQC@ delivers bottom-line results

Laser Fast (and Easy)

LaserQC@ captures over 500 data points per second to make part inspections laser-fast, right on the shop floor

Designed to set up easily so your system is up and running in less than a day. The intuitive user interface allows new operators to become fully proficient within just a few hours.

Laser Accurate

The system quickly performs 100% inspections accurate to ± 0.002″ (0.05mm) for 2D measurements and ± 0.010″ (0.25mm) for formed measurements.

Shop Floor Friendly

LaserQC@ offers a reliable, low-maintenance solution that operates along side your facilities CNC equipment.

The system self-calibrates and adjusts system settings to accommodate for environmental changes common to the shop floor.

Additionally, Virtek offers a Part Stabilizer add-on, created specifically for use in the gasket and seal industries.

Get the Edge in 2D and Formed Part Inspection

First Article Inspection

Integrating laser inspection on your shop floor translates into more ‘green-light’ time for your production equipment.

Accuracy Dashboard

LaserQC@ makes first part inspection fast and easy with no special training required. Color codes indicate any part deviations.

2D Reverse Engineering

The scanning process captures the complete profile of existing parts or templates at laser speed.

SPC & Quality Reporting

Inspection data from the LaserQC@ is saved as CAD files, from which can generate color inspection reports to your specifications.

Applications

ViRTEK IRIS 3D

Laser templating and positioning systems accurately project a virtual laser template onto molds and parts to guide operators through part fabrication whether it be ply layup, paint masking, assembly, or part placement. Virtek Iris™ significantly advances laser-guided assembly with new integrated vision technology, innovative “FlashAlign” functionality, superior high visibility laser- -line, and new multi-tasking capabilities. The thin-client experience boasts a unique offering. Initial alignment is 20X faster and re-alignments are reduced from minutes to seconds – saving time, and increasing workflow productivity, all while retaining quality and accuracy.

Applications

Features

FlashAlign™

Multi-Tasking

Production Reporting Database

Auto Focus & High Visibility

Simplified Software Interface

Projected Cross Hair

Field Replaceable Components

Projected Menus

Focus of Attention

Multi-Tasking

Production Reporting Database

Auto Focus & High Visibility

Simplified Software Interface

Projected Cross Hair

Field Replaceable Components

Projected Menus

Focus of Attention

Benefits

Instant alignment of the part or tool virtually eliminating set up time.

Multi-Tasking enables one projector to serve multiple workstations so ply layup on multiple parts can occur in parallel. The new thin client experience allows you to use one Iris 3D license to connect several PCs or tablets to serve as clients.

Easily access any Iris 3D system to retrieve instantaneous feedback on production status or retrieve historical data detailing the completion of each step in any production work-flow executed in the past.

Auto-Focus fiber connected laser source with optional long range optics. Provides operators with a brighter, safe laser delivering superior visibility even in the brightest work environments.

Reduced training & fewer operator errors, simplified operation and administration.

Automatically project crosshairs to indicate drill locations, punch locations, assembly positions. Crosshairs work on both flat and curved surfaces.

Flexibility of onsite repair of multiple components within the system such as laser, and cooling fan helping to reduce cost of ownership.

Work seamlessly from anywhere with remote capabilities, using the projected menus on the tool or part, or using the wireless remote controller at a 45m range.

Reduces projection flicker on-demand by limiting the projection to just the area of interest for increased visibility.

Hexagon

Hexagon Sheet Metal Fabrication Suite

A suite of best-in-class products offering an integrated workflow from design to quoting through production preparation, CAM and automation all the way to delivery and invoice while enhancing efficiency, reducing costs, and ensuring consistent quality from design to production.

Integrated Sheet Metal Fabrication for Precision and Efficiency

Engineered to address the critical challenges of sheet metal fabrication, offering solutions that boost productivity, enhance accuracy, and drive superior quality. Experience the difference with a suite that not only help you meet but exceeds industry standards for operational excellence.

Hexagon

- Quoting:

- CAD:

- CAM – Bending:

- CAM – Cutting

- Management:

Hexagon Quoting

Quoting for Sheet Metal Fabrication

Efficient quoting is crucial for competitive pricing and successful project management in sheet metal fabrication. Our Sheet Metal Suite offers a sophisticated quoting tool designed to simplify and enhance this process.

- Fast, Automatic, and Precise: Quickly generate accurate quotes that automates calculations and ensures precision. This speed and accuracy enhance the quoting process, allowing for rapid response to customer inquiries and faster turnaround.

- Single Part Support: Our solution provides detailed cost estimates for individual parts, ensuring accuracy and efficiency in every quote.

- Part Level and Assembly Level Operations: Perform quoting operations at both the part and assembly levels, allowing for detailed cost breakdowns and accurate pricing across different stages of fabrication.

- Calculations Using Actual Machine Knowledge: Benefit from quotes based on real machine data and operational knowledge. The software uses actual machine capabilities and constraints to ensure that quotes reflect realistic production costs and feasibility.

Hexagon CAD

CAD for Manufacturing & Design Reviews

Offers powerful features to enhance design accuracy and manufacturing efficiency and supports a thorough analysis and optimization of sheet metal parts, ensuring that designs are both manufacturable and cost-effective.

- Import Major File Formats: Import major file formats for both single parts and assemblies, ensuring compatibility with various design systems and facilitating smooth integration into your workflow.

- Verify Manufacturability: Assess the manufacturability of designs to ensure that they meet production requirements and constraints, preventing potential issues before moving to manufacturing.

- Automatic Part Recognition and Classification: Automatically recognize and classify parts within designs to streamline the review process and improve accuracy in design assessments.

- ‘Manufacturing Pack’ for System Consumption: Generate a ‘Manufacturing Pack’ that can be consumed by other systems, simplifying the transition from design to manufacturing and ensuring consistency across platforms.

- Fast Processing of Assemblies: Quickly process assemblies for quoting and manufacturing, accelerating the workflow and improving response times for quotes and production scheduling.

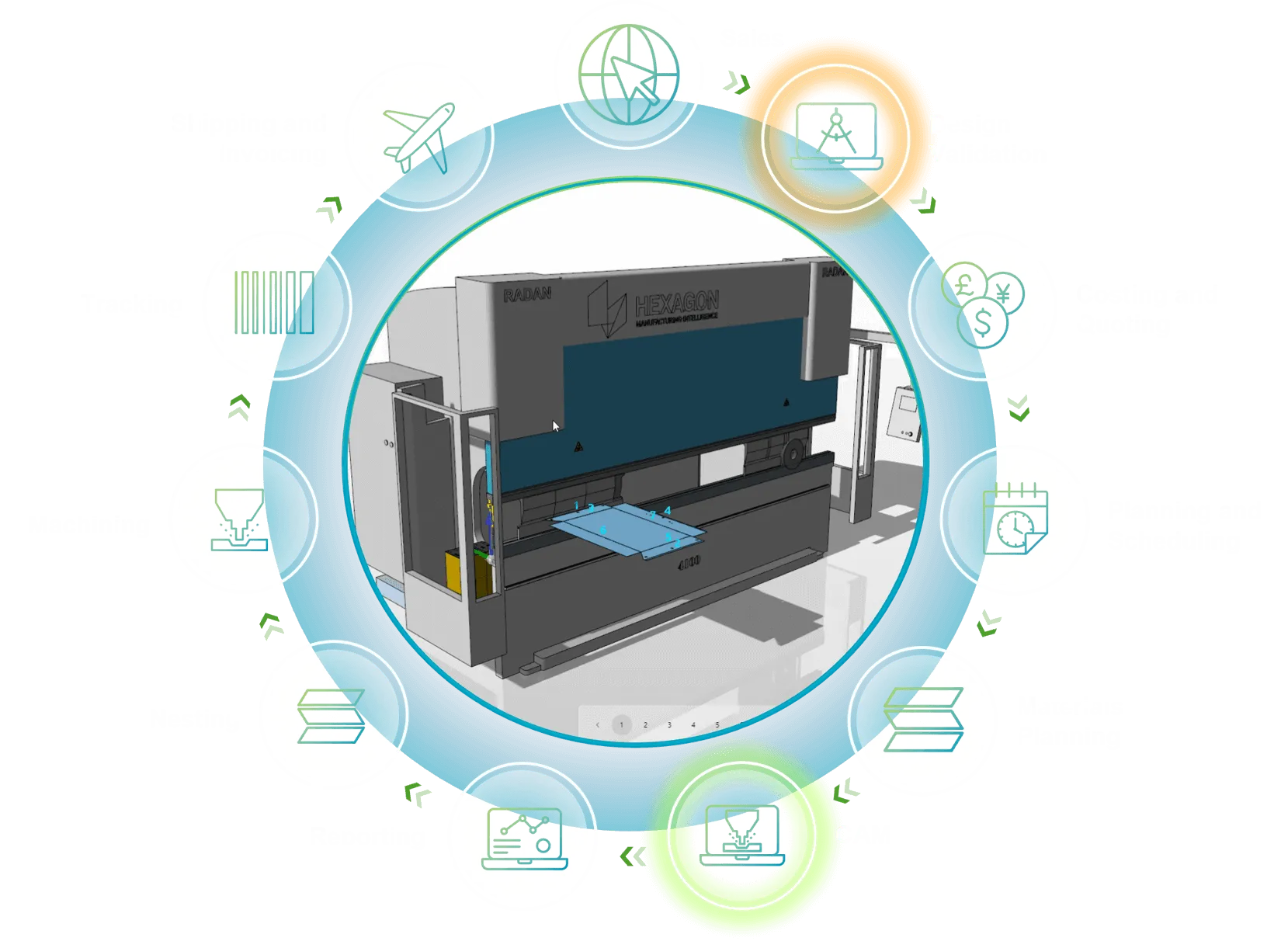

Hexagon CAM – Bending

CAM for CNC Bending

The CAM for CNC Bending module offers a comprehensive solution to streamline and enhance bending operations for press brakes. With features like offline programming, 3D simulation, and automatic process calculations, this tool ensures precision, efficiency, and reduced production time.

- Integrated with DESIGNER: Seamlessly integrates with DESIGNER, allowing for efficient design data transfer and workflow continuity between design and manufacturing.

- Automatic Unfolding and Verification: Automate the unfolding of 3D models and verify them against manufacturing constraints, ensuring accurate flat patterns and manufacturable designs.

- Automatic Process Calculations: Utilize automatic sequence calculation to determine the most efficient bending process, optimizing bending order and minimizing unnecessary steps without requiring manual intervention.

- Postprocessing: Efficiently generate machine-specific code through integrated postprocessors, ensuring that bending programs are tailored to the exact requirements of each press brake.

- Operator Instructions: Automatically generate detailed setup and operation instructions for machine operators, reducing the risk of handling errors and ensuring consistent output across production runs.

Hexagon CAM – Cutting

CAM for CNC Sheet and Tube Cutting

The CAM for CNC Sheet and Tube Cutting module offers a toolset for optimizing cutting operations across a range of technologies, including laser, plasma, and punch. Designed for both simple profiles and complex multi-axis operations, this solution ensures accuracy, efficiency, and flexibility for various manufacturing needs.

- Efficient and Safe Tool Paths: Generate safe and optimized tool paths that reduce machine wear and minimize operational risks, ensuring smooth and reliable cutting performance.

- Advanced Nesting Capabilities: Improve material utilization with class-leading nesting algorithms that optimize sheet layouts, reducing waste and driving significant material savings.

- Built on Extensive Industry Experience: Developed with decades of experience in the sheet metal and tube cutting industries, offering a proven and reliable solution trusted by leading manufacturers.

- Shop Floor Reports: Generate detailed shop floor reports that provide insights into production performance, material usage, and job completion, supporting data-driven decision-making.

- Preferred Solution for Major OEMs: Recognized as the go-to solution for significant OEMs across industries, ensuring compatibility with industry standards and best practices.

Hexagon Production Management

Production Management

Designed to streamline and integrate the entire production process for sheet metal fabrication and tube assemblies. From initial quoting and planning to final invoicing, this solution provides end-to-end visibility and control, ensuring seamless operations and consistent quality output.

- From Estimate to Invoice: Provides end-to-end control, managing the entire production cycle from the initial cost estimate to the final invoice. It ensures seamless integration across all stages—quoting, planning, nesting, production, and quality control—giving you comprehensive oversight and streamlined processes.

- Quoting for Sheet Metal and Tube Assemblies: Generate accurate and competitive quotes and supports detailed, itemized quotations, enabling precise cost estimation for single parts or complex assemblies while providing flexibility for adjustments.

- Nesting Connected to Stock and Inventory Management: Optimize material usage with intelligent nesting algorithms linked directly to your stock and inventory management system. This connection ensures efficient material allocation, reduces waste by tracking off-cuts and remnants, and keeps inventory levels updated in real-time, preventing material shortages and excess.

- Part Requirements Sourced from Connected ERP/MRP Systems: Leverage seamless integration with ERP/MRP systems to source part requirements directly from your production schedule. This integration ensures that production runs smoothly with real-time access to inventory, part availability, and order status, minimizing delays and maintaining alignment with business goals.

- Output to Quality Management Systems: Ensure consistent quality and compliance with integrated quality management features. The system automatically routes production data and outputs to quality control, helping to detect deviations early.

Eagle eSmart Cutting Machine Specifications

eSmart

The eSmart series presents the most cost-effective machines, designed with efficiency and reliability at the core. They require

little floor space but deliver great results.

With cutting speeds of up to 100m/min, acceleration up to 2G, and fiber laser powers of 1 to 10kW, the eSmart series delivers

precision, efficiency, and value.

STANDARD EQUIPMENT

Benefits of eSmart

- Made for 24/7 automation

- Flexible range of material thicknesses

- Cost-efficient technology

- Intelligent design to minimize footprint on floor space

- Reduced maintenance and services required

- Reduced energy consumption

- Easy to operate

- Easy and fast turnaround

- Flexible configurations and options to fit any budget

- Best performance and reliability on the market

Eagle eVision Cutting Machine Specifications

eVision

The eVision laser cutting machines are universal and provide the best results for any production. Whether you run large or small

batches, cut thin or thick sheets, this series will deliver optimum results 24/7.

With a top cutting speed of 150m/min, positioning speed of 200m/min, acceleration up to 3G, and fiber laser powers from 1 to

40kW, the eVision systems are ready to take your shop’s production to the next level.

STANDARD EQUIPMENT

Benefits of eVision

- Made for 24/7 automation

- Flexible range of material thicknesses

- Best efficiency and precision

- Intelligent design to minimize footprint on floor space

- Lowest maintenance on the market

- Reduced energy consumption

- Intelligent construction made to last

- Lowest cost per part

- Best throughput quality

- Best performances and reliability on the market

CSM CNC Tube Bending Machines Product

CNC Tube Bending Machines Machine Product

CSM’s CNC tube bending machines, available through CutTech, set the global standard in tube bending technology. With over 24 international design patents, these machines offer exceptional performance and flexibility for processing metal tubes.

Key Features:

- Planetary Gear Transmission System: Ensures smooth, high-precision bending with consistent results across all tube diameters.

- Range of Capability: Can bend various diameters of tubes ranging from 6 mm up to 254 mm, thus it is well suited for the varied size tubes that exist in most industries.

- Advanced Control System: With great ease through user friendly CNC control, the complex bending pattern is achievable, and time cycles are reduced.

- Durability & Reliability: Durable parts are used to ensure long-lasting performance even at demand-high usage times.

- CSM’s CNC Tube Bending Machines: The PRECISION and EFFICIENCY That Industries Like Automotive, Aerospace, Construction, and Manufacturing Require for Small- and Large-Scale Production.

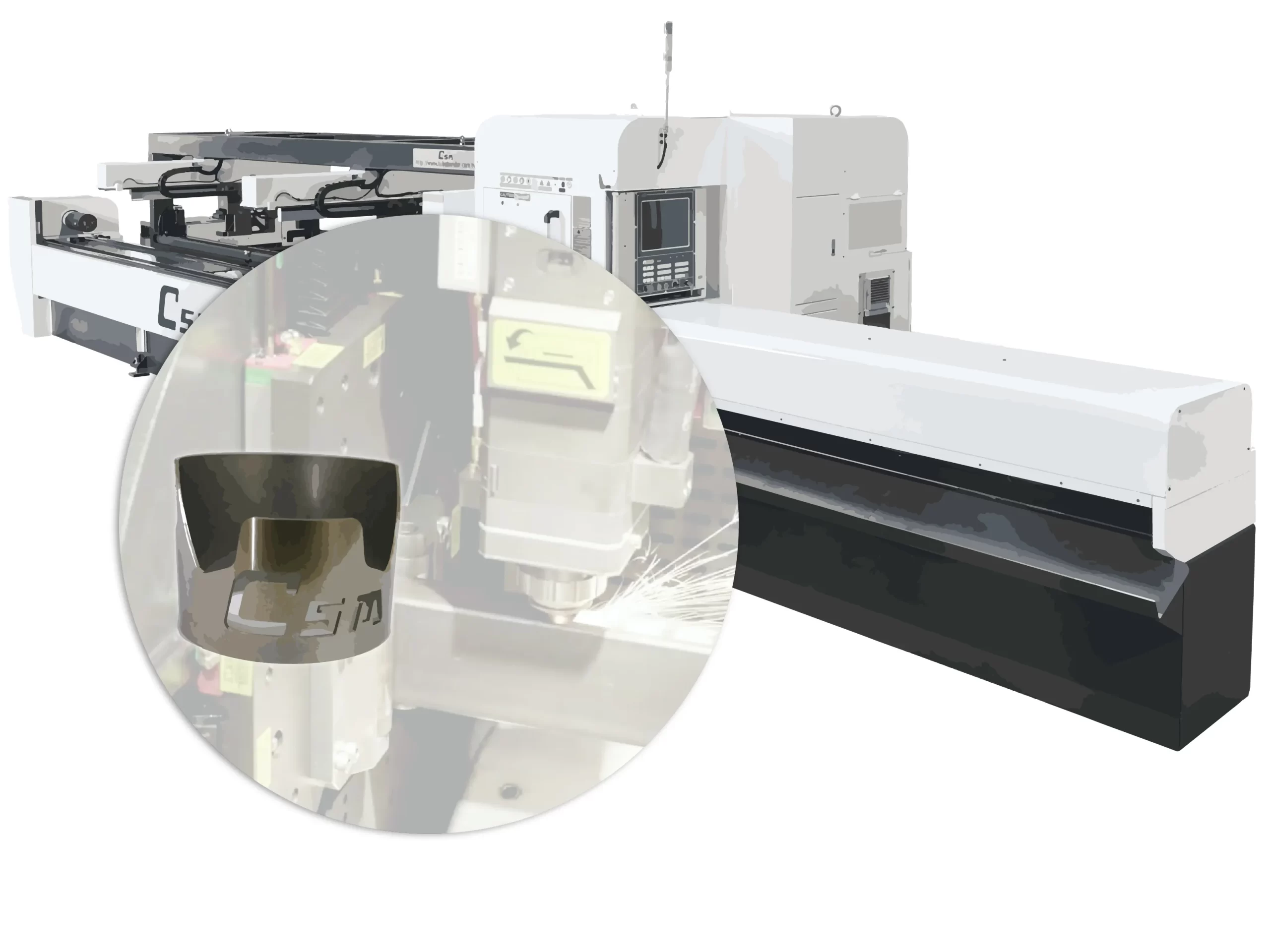

CSM Laser Cutting Product

Laser Cutting Product

CutTech Company is pleased to introduce CSM’s newest tube laser cutting technology, specifically designed and engineered for precision and versatility. Tube laser cutting machines from our brand are equipped with international design patents and 5-axis simultaneous movement technology that ensures leading-edge performance in cutting for the most complex geometries of tubes.

Main Features:

- High Precision: Position accuracy up to ±0.03 mm, with the highest possible detail and precision.

- High Speed Motion System: 5-axis simultaneous movements allow for complex and precise cuts at a variety of angles and orientations.

- Energy Saving: Designed using energy saving technology to reduce the cost of running.

- Versatility: Cuts tubes in different materials and thicknesses, providing flexibility for unmatched applications.

Laser cutting by CutTech and CSM is suitable for industries that require high-speed and high-precision cutting of tubes without having wastage of material.

CSM End Forming Product

End Forming Product

CutTech’s end forming machines by CSM help in making the best quality of end-formed tubes with minimum accuracy and speed. These are inevitable pieces of tube fabrication, where it provides versatility along with reliability for creating different tube end shapes for numerous applications.

Key Features:

Precision End Forming: It is capable of performing operations involving flaring, swaging, reducing, and beading, with a pretty high degree of precision.

Multiple Industries: Being widely applicable in various industries, such as automotive, HVAC, plumbing, and manufacturing, where specific shapes are necessary in the assembly or connection of tube ends.

Customized: The end forming process can be designed for varying sizes of tubes and processes, allowing for flexibility in design and production.

High Throughput and Excellent Quality: The machines are engineered for high throughput, thus reducing cycle time, but without compromising accuracy and quality in end forming.

With CSM’s advanced end forming machines, your tube parts are guaranteed to meet extremely stringent specifications for functionality and durability.